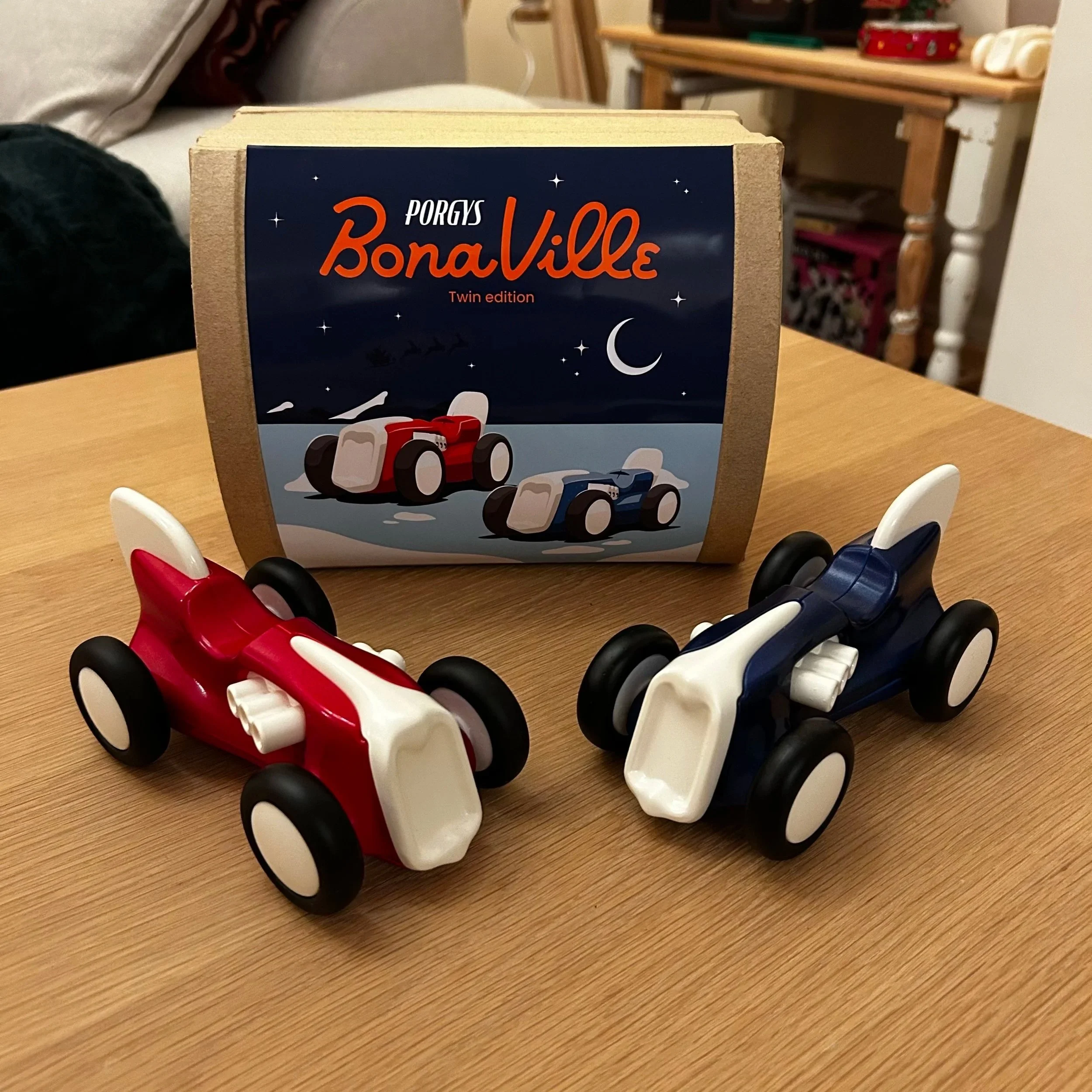

Porgys Toys

Porgys toys was my attempt at creating a sustainable toy line.

Made from fast grown soft woods and CNC machined. It was purposely small scale and completed entirely by myself.

I decided to pursue the idea of creating low production run product, as I felt that 3D printers had become accurate enough I could use them for fixturing for the CNC. This would reduce the cost and time required to get the product off the line.

A Brief Pause

In the end, world events sent the cost of the specific soft wood I was using through the roof, the price of the CNC bits I needed tripled in cost. In the end, my margins were too fine, and I didn’t personally feel the product was worth the cost at a higher rate.

So there Porgy’s died for a while.

Unfinished Business

It’s been two years, I have a niece and nephew. SO… Is 3d printing Good enough now to possibly make a porgy’s?

Initial trials proved successful, yes the material was less eco friendly, but the energy usage was significantly lower. It was easier to make, easier to paint, easier to assemble.

Iterations on the design allowed for a screw and glue free design. The whole thing clipped together.

The final design seemed perfect, rolled better than any previous version, the quality and finish was higher than any other version, the cost was lower.

It had past all testing required for CE certification, but real world testing is another thing?

By design there is a level of tension holding the piece together, this combined with a change of brand of ABS replica, which created parts with a unusually high amount of internal tension after printing.

In the end, it acted like a pane of tempered glass, strong in certain conditions, but if it hits a weak spot, that internal tension causes it to shatter…

And that is where this project currently stands, once again, on pause, looking for the next breakthrough.